Joining metal matrix composites to aluminum alloys for lightweight car brakes

Joining metal matrix composites to aluminum alloys for lightweight car brakes

Aluminum alloys are light-weight and one of the most interesting material solutions to optimize the strength/weight ratio to reduce car weight, however they are also relatively soft and therefore cannot be used for intensive wear applications.

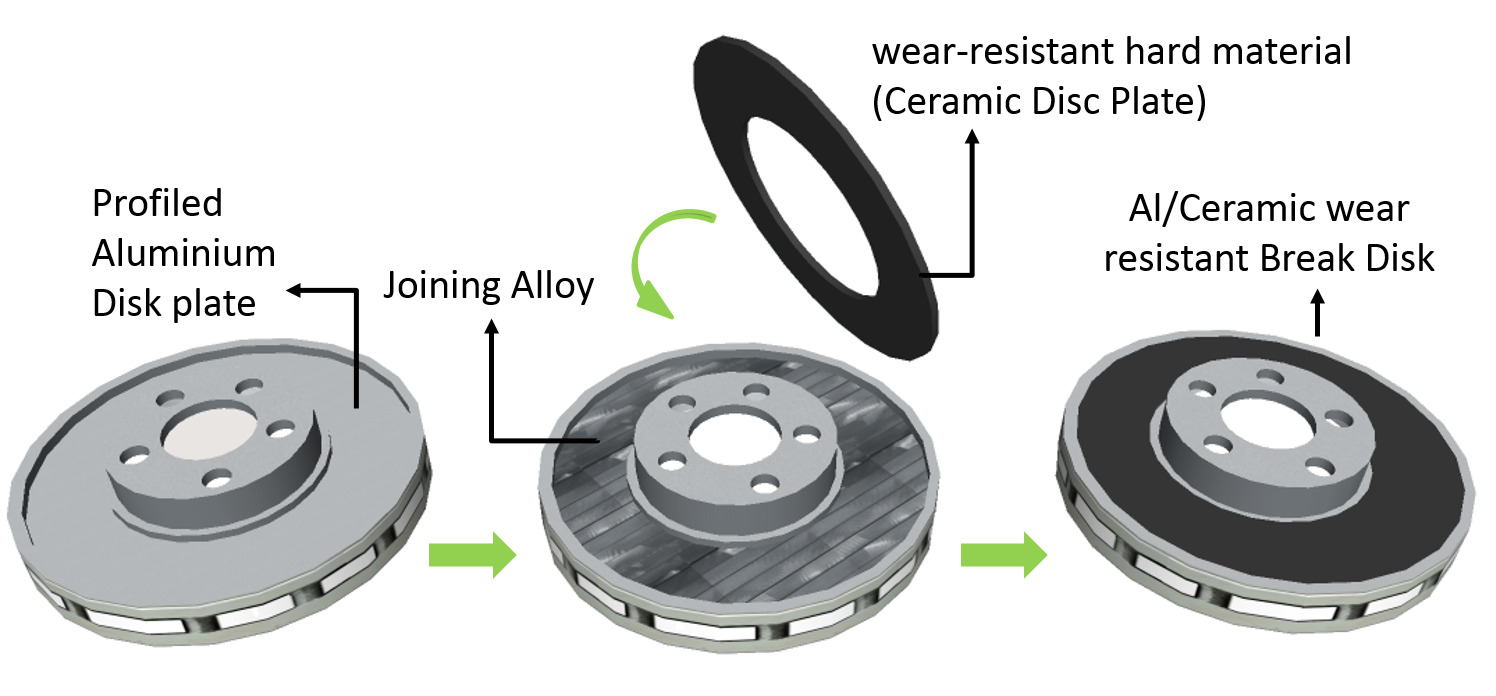

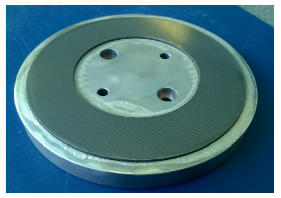

We developed an aluminum alloy combined with hard and wear-resistant Al2O3-based ceramic and/or a metal matrix composite with aluminum matrix and SiC particles (Al/SiCp-MMC) for demanding mechanical parts for automotive industry such disc brakes.

Tribological tests of various engineering ceramic materials and metal matrix composites (MMCs) were performed in order to find a material with proper coefficient of friction and thermal energy dissipation for the car brakes. Al/SiCp-MMC showed promising properties.

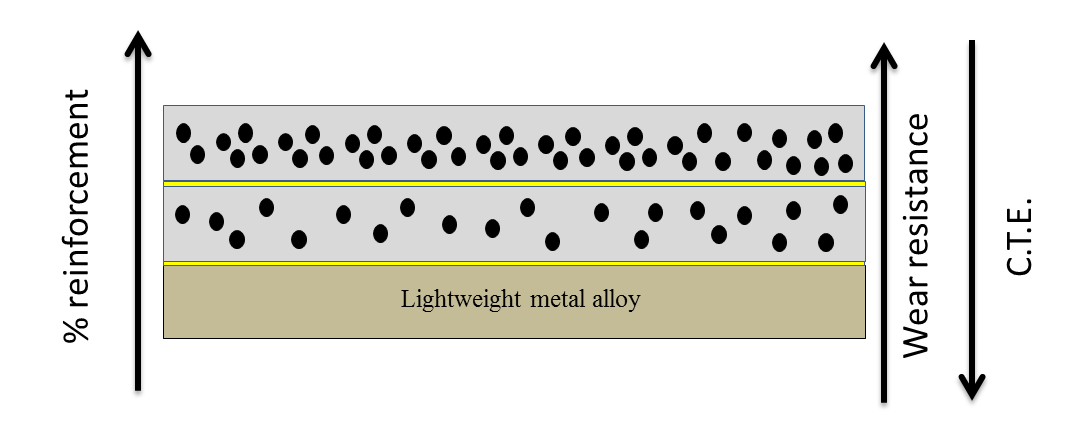

Different approaches, based on soldering and brazing technologies were used to join the hard materials to the aluminum surface. A functional graded structure was built by brazing layers of metal matrix composites with progressively higher amount of SiC particles using the ZnAl filler metal to address the thermal stresses.

Comparable tribological properties to those of the bulk material were achieved.

Keywords: joining, metal matrix composites, brazing, wear resistant materials, brakes, lightweight materials

Recent reference(s)

1. Gorjan, L., Boretius, M., Blugan, G., Gili, F., Mangherini, D., Lizarralde, X., Ferraris, M., Graule, T., Igartua, A., Mendoza, G., Kuebler, J.

Ceramic protection plates brazed to aluminum brake discs

(2016) Ceramics International, 42 (14), pp. 15739-15746.

2. Gorjan, L., Blugan, G., Boretius, M., De La Pierre, S., Ferraris, M., Casalegno, V., Rizzo, S., Graule, T., Kuebler, J.

Fracture behavior of soldered Al2O3 ceramic to A356 aluminum alloy and resistance of the joint to low temperature exposure

(2015) Materials and Design, 88, pp. 889-896.