Joining and testing of alumina fibre reinforced oxide fiber reinforced/oxide fiber reinforced matrix composites (Ox/Ox CMC)

Joining and testing of alumina fibre reinforced oxide fiber reinforced/oxide fiber reinforced matrix composites (Ox/Ox CMC)

Ox/Ox CMC are composed of oxide fibres (e.g., alumina based Nextel™ 610, Nextel™ 720 and CeraFib 75) and oxidic matrices (e.g. alumina, YAG, zirconia, mullite) with a suitable combination of low density and reliable thermo-mechanical properties; this makes them potential candidates for harsh environments and high temperature applications by replacing existing alloys, thus reducing fuel consumption, noise and CO2/NOx emissions.

In order to exploit the full potential of Ox/Ox CMC, it is necessary to develop reliable joining methods and materials able to withstand elevated temperatures in harsh environments.

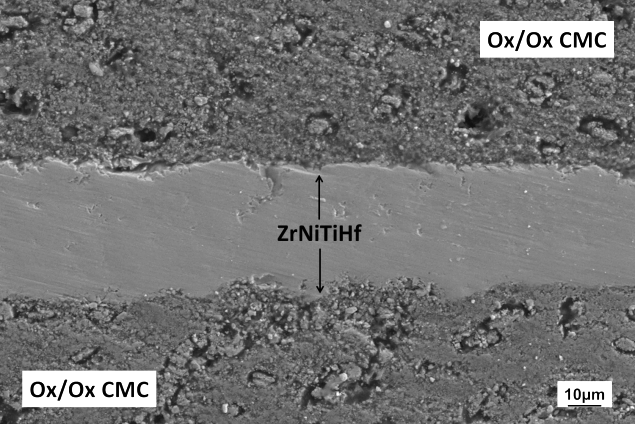

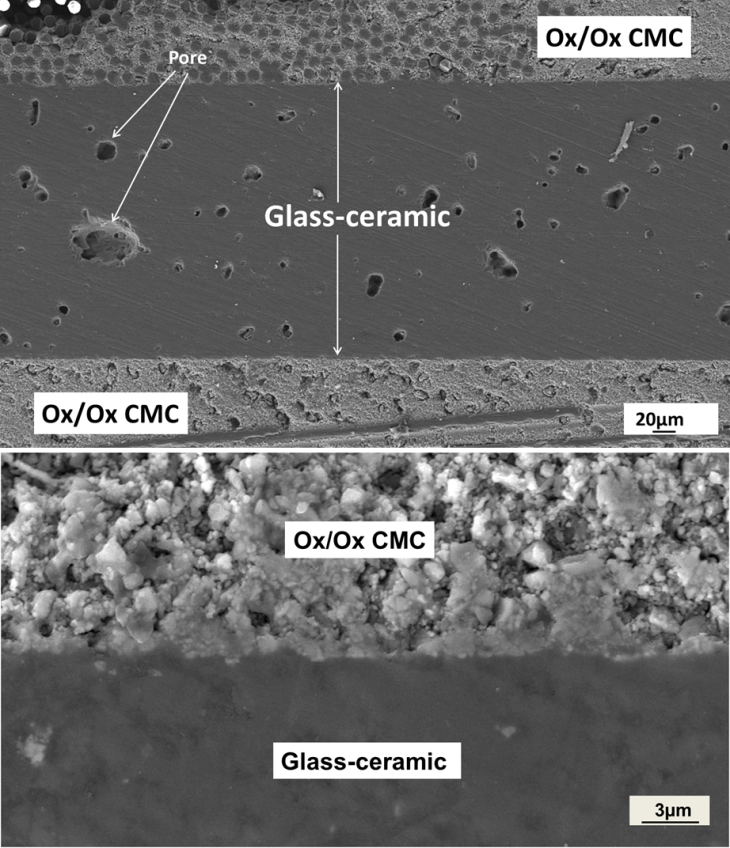

We successfully joined Alumina (Nextel™ 610) fibre reinforced YAG-ZrO2 matrix composites by using different brazing alloys, metallic interlayers and a glass-ceramics. All joints were mechanically stable and free of cracks and retained most of their mechanical strength at working temperature.

Three commercial brazing alloys and a new alloy based on Ti/Cu/Al interlayers were selected to join these composites for applications in a non-oxidizing environment. Several glass-ceramics based on SiO2-Al2O3-CaO-MgO were developed and tested at room and working temperature.

Four point bending tests on glass-ceramic joined samples showed an average joint strength of about 70 MPa which is 35% of as-received composites.

Joining of Oxide fiber reinforced Oxide matrix composites (Ox/Ox) by brazing alloys and glass-ceramics (ref. “Joining and testing of alumina fibre reinforced YAG-ZrO2 matrix composites” https://doi.org/10.1016/j.jeurceramsoc.2017.11.026)

Keyword: joining, CMC, oxide/oxide