Coatings on SiC-based components for Light Water Reactors

Title: Coatings of SiC-based components for Light Water Reactors

Description

Our efforts are aimed to develop new materials for safer nuclear fission reactors. Light Water Reactors (LWR) are the most common and successful reactors employed today. This study aims to develop coatings for SiC-based materials having the following characteristics:

-

Resistance to hydrothermal corrosion and neutron irradiation

-

Oxidation resistance when exposed to high temperature and pressure

-

Retain fission products

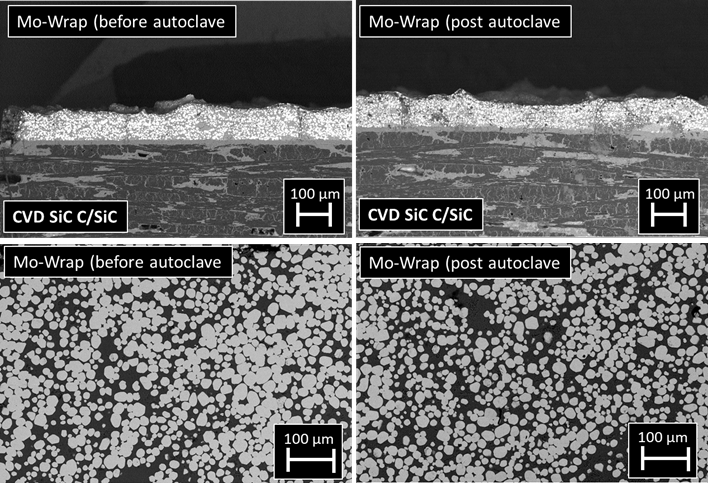

Reactive Metal (RM)-Wrap technology [1] , has been successfully used to coat C/SiC composites and preliminary tested in high pressure chemical reactor (autoclave, Supercritical Technology, USA, Prof. Luigi Manna laboratory DISAT-Politecnico di Torino, Italy, luigi.manna@polito.it) at 315-325 °C for 8 hours under a pressure of 150 bar with 8-9 ppm of dissolved oxygen.

Coating is composed of MoSi2 reinforced silicon matrix composite obtained by the Mo-Wrap technology, a pressure-less technology suitable to coat (and join) porous materials. [1]

RM-Wrap coated C/SiC composites, cross-section and top view, before (left) and after (right) preliminary test in autoclave, 315-325 °C 8 hours, 150 bar, 8-9 ppm of dissolved oxygen.

Keywords

C/SiC, coating, autoclave, LWR, RM-wrap technology

Contact(s)

Pardeep Kumar Gianchandani, Valentina Casalegno, Monica Ferraris (monica.ferraris@polito.it)

Recent reference(s)

-

Pressure-less joining of C/SiC and SiC/SiC by a MoSi2/Si composite. International Journal of Applied Ceramic Technology, (doi:10.1111/ijac.12631) 2017. 14(3): p. 305-312

This activity is partially funded by the EU project Il Trovatore (http://www.iltrovatore-h2020.eu/)